Proper design of wire transport systems

With the application of bulk wire systems (drums, large spools) instead of standard coils (7kg in aluminum, 15kg in steel) the use of conduits is necessary. At the same time the constancy of the wire feed speed is a crucial parameter in arc- or beamwelding. The movement of the electrode wire in the wire guide hose is inhibited by friction and it can very easily lead to situations in which the wire speed required can no longer be maintained

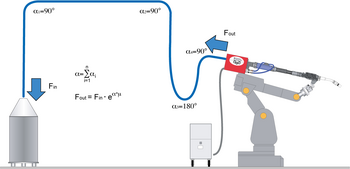

Thus, the correct design of the entire wire guide system is crucial. Own research and practical experience from MIGAL.CO has shown that the formula from Euler-Eytelwein is sufficiently accurate to design wire transport systems for a stable long-term operation. The following informations are necessary:

- Required force in Newton to pull the wire out of the bulk pack

- Pulling force of the wire feeder in Newton which can be safely maintained uring continuous operation

- Friction coefficient of conduit

- Sum of the radii of the conduit in degrees

The products of MIGAL.CO are uniquely matched to each other, thereby guaranteeing optimum wire transport and reliable welding processes in large scale production.

Friction coeficient of MIGAL.CO conduits

| Conduit | Typo of friction | Friction coefficient |

|---|---|---|

| Rolliner NG, 3G | Rolling friction | 0,08 |

| Rolliner XL2 | Rolling friction | 0,08 |

| Toughliner | Sliding friction | 0,20* |

| Softliner | Sliding friction | 0,20 |

* for steel wires only. Toughliner cannot transport aluminum wires!

Extraction force from MIGAL.CO drums

| Type of drum | Extraction force [N] |

|---|---|

| Eco-drum aluminum with decoiling aid ASH 80 | 1,5 N (MA-4043 1,6mm) |

| Jumbo-drum with decoiling aid TOU400/580 | 1,0 N (MA-5087 1,2mm) |

| Eco-drum CrNi with decoiling ring | 0,6 N (ML 18.8 Mn 1,2mm) |

Calculation of transport forces for the proper design of wire transport systems

With the following calculation form the application of the Euler-Eytelwein formula for designing a wire transport system is possible.

The following entries are to be made:

- Extraction force Fin in Newton - how much is for example the force required to pull the wire out of the drum (see table)

- Angle α in degrees - Sum of the bending angles with which the conduit is installed

- Friction coefficient µ (see table)

It calculates the force with which the wire feed motor has to pull. You can enter a maximum value (eg, 30 N). The values are also displayed graphically in the diagram.