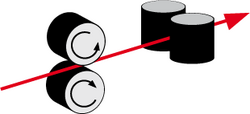

Rolliner NG - the second generation

ROLLINER NG is the second generation of a completely new approach to wire feeding, already. Away from friction in liners, away from abrasion, from fluctuating feeding and from unnecessary maintenance. With ROLLINER feeding occurs through rolls only, shifted by 90° - without any sliding friction. ROLLINER NG has a reduced diameter of 20mm only and may be shortened or lengthened easily – without any tools. The maximum bending radius is 120 mm only and the weight was substantially reduced – ideal for highly dynamic movements.

Application

- Connecting bulk-wire systems to the wire-feeder

- Connecting wire-feeders to welding guns

Advantages

- No abrasion due to extremely small forces on the wire

- Reduced cost due to the reduction to one wire drive only, and no maintenance necessary

- Stable arc due to precise wire feeding

- Simplified setup of welding systems due to more freedom in situating the bulk-wire system

Technical data

| Outside diameter | 20 mm |

| Weight/meter | 150 Gramm |

| Min. bending radius for wire inching | 150 mm |

| Min. bending radius | 120 mm |

| Maximum torsion | 180°/Meter |

| Max. inner diameter | 2mm (wire 1,6) |

| Recommended wire diameter | 0,6-1,2 mm |

| Length per packaging unit | 25 m Rolle |

| Coefficient of friction | 0,08 |

Possible applications

Components

Connector ENG-20S and strain relief RES20

Connector ENG-20S, protective hose PA-12 and adapter RPA12

For applications with robotic systems, very fast movements and extreme bending the Rolliner NG may be additionally protected with a cover hose made from PA 12. Brackets and wear rings are available as shown on the image.

Usually the protection is required in the area of extreme movements only. The outside diameter is 28.5mm.

For a complete conduit it requires Rolliner NG (10,30,1,0100), the connector ROLLINER NG - ENG 20S (10,30,1,0016), the protective hose PA12 (10,30,1,0007) and the adapter RPA12 (10,30,1,0018).

This is the standard setup for a total length of more than 3 m.

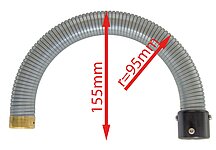

Special bend protection PMF-20 for confined spaces

Applications requiring that the Rolliner NG is connected directly to the welding torch or other confined spaces occur, often need a very small bend radius. In such cases it frequently occurs that the minimum bend radius falls short or the Rolliner even breaks. For such applications a special-bend protection was developed. This assures that the minium radius is maintained and damage is prevented.

The special bend protection PMF20 is connected by the adapter ENG20S.

The special bend protection PMF20 can be used together with the protective hose PA12 in connection with the adapter RPA12M.

Elbow pipe CD-90

The elbow pipe CD90 consists of a sturdy aluminum tube and serves as a strain relief for the Rolliner NG. This can for example be used to avoid the minimum bending radius when connecting to a drum.

Subsequently, the transition to the protection PA12 hose with the adapter RPA12M is possible.

Hose holder and accessories

For the Rolliner NG, as well as the protective hose PA12 suitable brackets and wear rings are offered.

Reference table

| Designation | Item number | Weight [kg] | Qty in stock |

|---|---|---|---|

| Wall bracket for Rolliner NG SNG20 | 10,30,1,0006 | 0.02 | 44 |

| Protective hose PA12AD285 | 10,30,1,0007 | 0.1 | 380 |

| Wear ring for protective hose PA12AD285 | 10,30,1,0009 | 0.02 | 29 |

| Wall bracket for protective hose PA12AD285 | 10,30,1,0010 | 0.05 | 72 |

| Hose holder for Rolliner NG and PA12AD285 | 10,30,1,0014 | 0.1 | 14 |

| Connector Rolliner NG ENG20S | 10,30,1,0016 | 0.04 | 58 |

| Strain relief for Rolliner NG RES20 | 10,30,1,0017 | 0.15 | 119 |

| Adapter RPA12 | 10,30,1,0018 | 0.03 | 98 |

| Rolliner NG | 10,30,1,0100 | 0.15 | 1026 |

| Special bend protection PMF20 | 10,30,1,013 | 0.05 | 41 |

Instructional videos

Additional information

ENG-20S Stepdata68 KB

ENG-20S Stepdata68 KB

RES-20 Stepdata1 MB

RES-20 Stepdata1 MB

RPA-12 Stepdata297 KB

RPA-12 Stepdata297 KB

RPA-12M Stepdata317 KB

RPA-12M Stepdata317 KB

PMF-20 Stepdata152 KB

PMF-20 Stepdata152 KB

CD-90 Stepdata166 KB

CD-90 Stepdata166 KB