MIGAL.CO Sensorbox – Capture, Understand, and Connect Welding Process Data

- Time-synchronized multi-sensor capability: Current, voltage, wire feed and gas flow with a common time base

- Web dashboard for configuration, live display, and firmware updates

- 5 kHz sampling rate: According to the sampling theorem, frequency components up to approx. 2.5 kHz (Nyquist frequency) can be unambiguously measured

- High-speed raw data stream (UDP) for oscilloscope traces, FFT, U-I diagrams and histograms – ideal for test series and model development

- Deterministic measurement windows & sequence numbers (timestamp + seq) for reproducible evaluation and packet loss detection

- On-device feature calculation (U/I RMS, active power, statistical values) for rapid parameter determination without PC/cloud

- MQTT/JSON telemetry for easy integration into laboratory setups, data pipelines and time-series databases (e.g. InfluxDB)

- OPC UA Server – standardized interface for industrial integration

- Diagnostic and quality flags in the data stream (e.g. ADC overrun, encoder timeout, NTP sync) for clean data validation

- Dual-core architecture (measurement core + communication core) for stable measurement even under network and UI load

- NTP synchronization for comparable timestamps across multiple Sensorboxes/welding stations

- RoboScope (Windows/macOS) for live analysis: oscilloscope, FFT, waterfall diagram, histogram, U-I and U-I density – quickly from "signal" to "insight"

- Calibratable via zero point, gain, and encoder wheel circumference

- Integrated correction factor calculation for arbitrary gas mixtures of Ar, He, O₂, H₂ and N₂

- Export function of measurement data in the weldx format

- Direct transfer of measured values into WPS-Maker documents

- Storage and centralized monitoring in RoboCenter

- Modbus TCP (Port 502) - SPS-connection via Standard-Modbus-Protokol (Holding Registers)

The MIGAL.CO Sensorbox is a modular, microcontroller-based measurement and communication platform for high-resolution acquisition, processing, and forwarding of welding process data for arc welding processes. It was developed for the harsh industrial welding environment and forms the technical foundation for process monitoring, data-based quality analysis, and prospectively AI-supported defect detection.

With the Sensorbox, the user obtains welding data directly from the process – cleanly time-stamped, structurally packetized, and securely transmitted to the network. This enables:

- Making welding processes transparent (instead of relying on "gut feeling")

- Tracing parameters per weld seam / job / workstation

- Feeding data into InfluxDB, dashboards or cloud systems

- Implementing real-time visualization (oscilloscope/spectrum) or edge analytics

- Establishing the foundation for automated anomaly and defect detection

- Quickly and easily creating Welding Procedure Specifications (WPS) from real, measured welding data

System Architecture: Real-Time Measurement Meets Network & Analysis

Inside, an STM32H7 dual-core (Cortex-M7 + Cortex-M4) operates with a clear division of tasks:

- Cortex-M4: handles the time-critical measurement (high-frequency, deterministic)

- Cortex-M7: takes care of data preparation, analysis, protocols, network communication, and system control

Both cores exchange data via OpenAMP / RPMsg – with low latency, clear sequencing, and a robust structure.

Measured Variables: The Most Important Process Parameters Captured Synchronously

The Sensorbox currently captures:

- Welding current

- Welding voltage

- Gas flow rate

- Wire speed

Current & voltage are acquired with high temporal resolution via the STM32H7 ADCs in DMA circular mode. A 5 kHz sampling rate is achieved.

Gas flow rate and wire speed are fully integrated and are recorded synchronously with the electrical variables – ensuring time reference and correlation across all parameters.

Each measurement frame contains, in addition to the raw data, important metadata such as:

- Timestamp

- Sequence number

- Status flags

- Calibration parameters (gain/offset)

This allows raw data to be accurately converted into physical quantities on downstream systems – reproducibly and traceably.

Data Processing: Key Figures Calculated Directly on the Device

On the Cortex-M7, data is already preprocessed and analyzed. Currently available features include:

- RMS and mean value calculation

- Active power from current and voltage

- Scaling & acquisition of gas flow rate and wire speed

The data is then structured into packets and tagged with unique identifiers, so it can be clearly assigned to a job, a weld seam, or a workstation.

Communication & Networking: Securely into IT – Fast into Real-Time

The Sensorbox is fully network-capable via Ethernet (LwIP TCP/IP stack) and offers two central data paths:

MQTT over TLS (mbedTLS) – for IT, Cloud & Databases

Process data (current, voltage, gas, wire) is transmitted cyclically (typically 0.1 to 5 seconds) – ideal for:

- Cloud/server connections

- Process monitoring & reporting

- Storage in time-series systems (e.g. InfluxDB)

- Secure integration into existing IT infrastructure

UDP Real-Time Stream – for High-Frequency Live Data

For high-frequency and latency-critical applications, there is also a UDP data stream. Through this, raw measurement frames (current/voltage) can be sent to external systems with virtually no delay.

The UDP packets contain structured headers (including magic number, sequence numbers, timestamps, payload description) – ensuring that synchronization, validation, and traceability remain robust even in case of packet loss.

Typical use cases:

- Live visualization (oscilloscope or spectral display)

- Fast control/assistance systems

- Edge- or PC-based online analysis

Additionally, an integrated web server (Mongoose) is on board – for diagnostics, configuration, and future visualizations.

OPC UA Server – Standardized Interface for Industrial Integration

For easy connection to SCADA/MES/IIoT platforms, the Sensorbox provides an OPC UA server (opc.tcp). This allows welding data to be read out vendor-neutrally and without proprietary gateways by OPC UA clients such as UaExpert or Node-RED.

Provided measured values (read-only):

- Current (RMS) [A]

- Voltage (RMS) [V]

- Power [W]

- Gas flow [l/min]

- Wire speed [m/min]

The values are cyclically updated and are available in namespace ns=1 – ideal for live monitoring, data logging, or further processing in higher-level systems.

Time Base & Synchronization: Data with Absolute Time Reference

For precise temporal classification, the Sensorbox supports SNTP/NTP time synchronization. All measured values are tagged with absolute timestamps – important for:

- Correlation of multiple Sensorboxes

- Clean time-series analysis

- Later evaluation in InfluxDB & similar systems

Persistence & Configuration: Robustly Stored, Even During Power Drops

Device, network, and security parameters (e.g. IP configuration, MQTT credentials, UDP target address, TLS certificates) are persistently stored in internal flash.

A robust storage strategy with:

- Magic number

- Checksums

- Clearly defined flash sectors

ensures that configurations are preserved even during unexpected power loss.

In Brief

The MIGAL.CO Sensorbox is the bridge between the welding process and the data world:

Precise measurement, synchronized process data, on-device preprocessing, and secure or real-time-capable transmission – ready for monitoring, analysis, and the next level of quality assurance.

Messverfahren für Strom, Spannung und Leistung

Measurement Methods for Current, Voltage, and Power

The MIGAL.CO Sensorbox calculates precise process parameters for voltage, current, and power from high-frequency raw data at a 5 kHz sampling frequency. Voltage u(t) and current i(t) are captured in short time windows and digitally evaluated:

- RMS Voltage (U_RMS) and RMS Current (I_RMS) are the so-called effective values. They reliably describe the electrically "effective" quantity even when the signal is not sinusoidal – as is typical in welding.

- Power (P) is calculated as the mean of the instantaneous power: For each sample, u × i is computed and then averaged over the time window. This produces a stable power value that cleanly reflects real process changes (e.g. short-circuit phases, arc instability, wire/gas influences).

These key figures form the basis for live monitoring, trend analyses, quality evaluation, and subsequent AI-supported defect detection.

RMS-Voltage:

\[ U_{\mathrm{RMS}}=\sqrt{\frac{1}{N}\sum_{k=0}^{N-1} u[k]^2} \]

RMS-Current:

\[ I_{\mathrm{RMS}}=\sqrt{\frac{1}{N}\sum_{k=0}^{N-1} i[k]^2} \]

Mean Active Power:

\[ P=\frac{1}{N}\sum_{k=0}^{N-1}\big(u[k]\cdot i[k]\big) \]

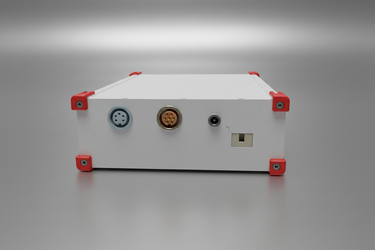

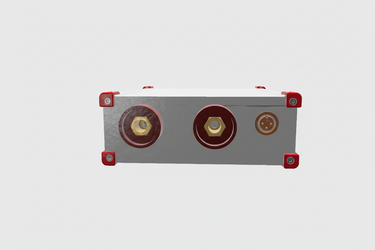

Technical data

| Interface | Ethernet (10/100 Mbit/s) |

| Data transmission protocol | MQTT (3.1.1 and 5), UDP, OPC UA, Modbus TCP |

| Web interface | For configuration and real-time display |

| Supply voltage | 9 - 12 Volts DC |

| Network | DHCP, static IP |

| Message frequency | MQTT: 0.1 - 5 per second, UDP: 50 frames × 256 values per second |

| Encryption | MQTT: TLS 1.3, UDP binary unencrypted |

| Sensorbox dimensions | 200 x 160 x 60 mm (L×W×H) |

| Sensorbox weight | 1.1 kg |

| Protection rating | IP 20 |

| Voltage measurement | - 60 to + 60 Volts (AC, DC), +/- 1% of full scale |

| Current measurement | - 600 to + 600 Amperes (AC, DC), +/- 1% of full scale |

| Wire diameter range | 0.8 mm – 1.6 mm (larger on request) |

| Encoder resolution | 0.114 mm, 600 pulses per revolution |

| Wire feed speed | 0 - 20 m/min |

| Wire speed accuracy | 0.7% at 10 m/min and 0.1 s sampling interval |

| Encoder weight | 0.40 kg |

| Gas flow rate | 0.5 - 50 l/min |

| Gas flow accuracy | +/- 3% of maximum value |

| Gas flow sensor weight | 0.10 kg |

MQTT-Message

The Sensorbox transmits its measurement and status data in a compact JSON (JavaScript Object Notation) format. Each message corresponds to a temporally uniquely assignable snapshot of the welding process and contains both process key figures and system states and firmware versions.

Time & Sequence

→ Used for synchronization with other systems (InfluxDB, dashboard, RoboScope, MES).

→ Allows detection of dropouts, packet loss, or gaps in the recording.

Electrical Key Figures

→ These quantities enable load/energy analysis, process stability assessment, and comparison of jobs/parameters.

Wire & Gas

→ Basis for process monitoring (e.g. insufficient feed, wire jamming, defect detection).

→ Already corrected in the Sensorbox so that the user directly receives a practically relevant value.

→ Transparency on how much raw values have been adjusted due to calibration/environmental influence.

Status Object (Health & Diagnostics)

Under status, important diagnostic flags are provided as booleans:

→ This enables remote diagnostics without the user needing direct access to the hardware.

Firmware Versions (Traceability)

Example:

{

"ts": "2026-01-21T10:15:23.123Z",

"seq": 4711,

"u_rms": 23.45,

"i_rms": 156.78,

"p_rms": 3680.2,

"wire_m_min": 8.50,

"gas_l_min": 12.30,

"gas_cf": 1.07,

"status": {

"openamp_ok": true,

"adc_overrun": false,

"encoder_timeout": false,

"ntp_synced": true

},

"fw": {

"m7": "1.0.3",

"m4": "1.0.3"

}

}UDP High-Speed Stream (Raw Data Packet)

For high-resolution analysis (oscilloscope view, histograms, event detection), the Sensorbox additionally sends a binary/CSV-like UDP data stream alongside the JSON telemetry. Each UDP packet contains a header with metadatafollowed by a block of ADC raw samples for voltage and current.

1) Packet Header (Metadata)

→ This allows the receiver to reliably identify data as a "Sensorbox frame" and discard erroneous or foreign packets.

Timestamp in milliseconds.

→ Enables time-correct display (e.g. live trace), logging, and synchronization with other sources.

Sequential sequence number.

→ Packet losses or ordering errors (UDP!) become immediately visible.

Number of samples per channel in this packet.

→ A packet is a "data block" (frame) with a precisely defined scope.

Current gas flow rate (l/min) as meta-information for the sample block.

→ Practical for directly correlating oscilloscope data with process parameters.

Wire feed speed (m/min) at the same point in time.

→ Can be 0 if the wire is stationary or an encoder/signal problem exists.

Bitmask for system states/error flags (e.g. ADC overrun, encoder timeout, OpenAMP OK, NTP sync).

→ Diagnostics without extra queries – each packet carries its health status.

Calibration/conversion parameters.

→ This allows the receiver to convert raw data to physical quantities (or deliberately store raw data and reconstruct later with the same parameters).

2) Sample Data (Payload)

After the header, a table/sequence follows:

→ From this, the receiver can:

- Generate oscilloscope traces (u(t), i(t))

- Calculate RMS/power/arc stability

- Detect peaks, short circuits, spatter events

- Create histograms/distributions (e.g. current distribution per job)

Why UDP?

UDP is ideal for live streaming large data volumes:

- Very low latency

- Low protocol overhead

- "Best effort" (packet loss possible) → therefore: seq in header

For robust storage/backfill, the "slow" telemetry channels (e.g. JSON via MQTT/HTTP) are usually used in parallel, while UDP serves for real-time viewing (RoboScope).

Example Python code for outputting the UDP stream in the terminal (call e.g. with python3 udp_dump.py 9000):

#!/usr/bin/env python3

import argparse

import socket

import struct

import math

MAGIC_OSCI = 0x3143534F # "OSCI"

FLAG_STATUS = 0x0001

FLAG_CAL = 0x0002

BASE_HDR_FMT = "<IHHII" # magic, header_len, flags, seq, sample_cnt

BASE_HDR_LEN = struct.calcsize(BASE_HDR_FMT) # 16

def parse_packet(buf: bytes):

if len(buf) < BASE_HDR_LEN:

return None

magic, header_len, flags, seq, sample_cnt = struct.unpack_from(BASE_HDR_FMT, buf, 0)

if magic != MAGIC_OSCI:

return None

# Minimaler Header: base + ts + meta

if header_len < (BASE_HDR_LEN + 8 + 8) or header_len > len(buf):

return None

off = BASE_HDR_LEN

ts_ms, = struct.unpack_from("<Q", buf, off)

off += 8

gas_l_min, wire_m_min = struct.unpack_from("<ff", buf, off)

off += 8

status = None

if flags & FLAG_STATUS:

if off + 4 > header_len:

return None

status, = struct.unpack_from("<I", buf, off)

off += 4

# Default Cal (falls nicht mitgesendet)

u_gain = 1.0

u_offset = 0.0

i_gain = 1.0

i_offset = 0.0

if flags & FLAG_CAL:

if off + 16 > header_len:

return None

u_gain, u_offset, i_gain, i_offset = struct.unpack_from("<ffff", buf, off)

off += 16

# Payload beginnt bei header_len

payload_off = header_len

payload_bytes = len(buf) - payload_off

available_samples = min(sample_cnt, payload_bytes // 4)

return {

"ts_ms": ts_ms,

"seq": seq,

"sample_cnt": sample_cnt,

"available_samples": available_samples,

"gas_l_min": gas_l_min,

"wire_m_min": wire_m_min,

"flags": flags,

"status": status,

"u_gain": u_gain,

"u_offset": u_offset,

"i_gain": i_gain,

"i_offset": i_offset,

"payload_off": payload_off,

}

def main():

ap = argparse.ArgumentParser(description="Simple UDP dump for MIGAL.CO Sensorbox OSCI stream")

ap.add_argument("port", type=int, help="UDP port to listen on, e.g. 9000")

ap.add_argument("--bind", default="0.0.0.0", help="Bind address (default: 0.0.0.0)")

ap.add_argument("--n", type=int, default=16, help="How many samples to print (default: 16)")

ap.add_argument("--rms", action="store_true", help="Compute simple U_rms/I_rms/P_mean from printed samples")

args = ap.parse_args()

sock = socket.socket(socket.AF_INET, socket.SOCK_DGRAM)

sock.bind((args.bind, args.port))

print(f"Listening on {args.bind}:{args.port} ... (Ctrl+C to stop)")

while True:

buf, addr = sock.recvfrom(65535)

info = parse_packet(buf)

if info is None:

# Unbekanntes Paket – leise ignorieren oder kurz melden:

continue

ts_ms = info["ts_ms"]

seq = info["seq"]

sc = info["sample_cnt"]

av = info["available_samples"]

gas = info["gas_l_min"]

wire = info["wire_m_min"]

flags = info["flags"]

status = info["status"]

u_gain = info["u_gain"]

u_offset = info["u_offset"]

i_gain = info["i_gain"]

i_offset = info["i_offset"]

print("\n" + "-" * 80)

print(f"from {addr[0]}:{addr[1]} ts_ms={ts_ms} seq={seq} samples={sc} (in packet: {av})")

print(f"gas_l_min={gas:.3f} wire_m_min={wire:.3f} flags=0x{flags:04x}", end="")

if status is not None:

print(f" status=0x{status:08x}")

else:

print()

if (flags & FLAG_CAL) != 0:

print(f"cal: u_gain={u_gain} u_offset={u_offset} i_gain={i_gain} i_offset={i_offset}")

# Samples ausgeben

nprint = min(args.n, av)

off = info["payload_off"]

u_vals = []

i_vals = []

for i in range(nprint):

w, = struct.unpack_from("<I", buf, off)

u_raw = w & 0xFFFF

i_raw = (w >> 16) & 0xFFFF

off += 4

# physikalisch (falls Gain/Offset gesetzt)

u = u_raw * u_gain + u_offset

cur = i_raw * i_gain + i_offset

u_vals.append(u)

i_vals.append(cur)

print(f"{i:4d}: u_raw={u_raw:5d} i_raw={i_raw:5d} u={u:.3f} i={cur:.3f}")

if args.rms and nprint > 0:

u2 = sum(x*x for x in u_vals) / nprint

i2 = sum(x*x for x in i_vals) / nprint

p = sum(u_vals[j] * i_vals[j] for j in range(nprint)) / nprint

print(f"-> U_rms={math.sqrt(u2):.3f} I_rms={math.sqrt(i2):.3f} P_mean={p:.3f} (über {nprint} Samples)")

if __name__ == "__main__":

main()

OPC UA Variable Nodes

The server exposes 5 read-only variables in namespace ns=1:

| Variable | NodeID | Type | Unit | Description |

|---|---|---|---|---|

| Current | ns=1;i=6001 | Double | A | Root mean square (RMS) |

| Voltage | ns=1;i=6002 | Double | V | Root mean square (RMS) |

| Power | ns=1;i=6003 | Double | W | Instantaneous power |

| Gas flow | ns=1;i=6004 | Double | l/min | Corrected volume flow |

| Wire speed | ns=1;i=6005 | Double | m/min | Encoder-based |

Modbus TCP (PLC connectivity)

Modbus TCP is a widely used industrial protocol for communication between programmable logic controllers (PLCs) and field devices. The Sensorbox provides an integrated Modbus TCP server that allows a PLC to read the key welding process parameters directly as Holding Registers.

This interface can be extended with writable registers, enabling a PLC or robot controller to actively transmit information to the Sensorbox – such as the current weld seam ID, job number, or program number. This enables complete traceability and quality documentation for every single weld seam.

This allows your robot controller to communicate with the Sensorbox in real time – the foundation for automated quality assurance in connected welding production.

Contact us – we will work with you to develop the right integration for your existing automation infrastructure.

Scope of Delivery

- Sensorbox with microcontroller and connectors for Ethernet, power supply (9–12 V DC) and encoder, 12 V plug-in power supply and PoE adapter, 3-pin cable connector for voltage measurement with 5 m twisted measurement cable.

- Wire sensor (encoder) with 1.5 m cable and 5-pin cable connector.

- Gas sensor with 2 m cable and 7-pin cable connector.

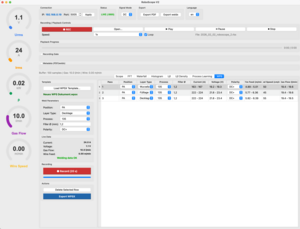

RoboScope Software for Welding Data Visualization

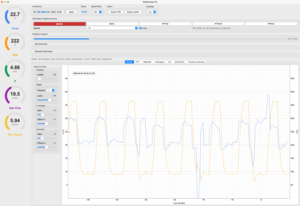

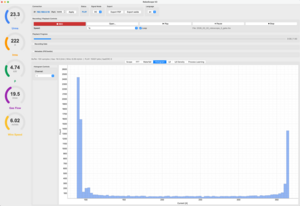

RoboScope is the companion PC software for the MIGAL.CO Sensorbox and is available for Windows and macOS. It serves for live visualization, analysis, recording, and diagnostics of captured welding process data – ideal for commissioning, process optimization, and troubleshooting directly at the workstation or in the laboratory.

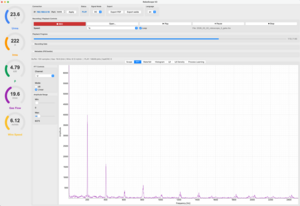

Live Visualization (Oscilloscope)

RoboScope displays the current and voltage waveforms in real time (typically via the UDP real-time stream). This makes peaks, dips, instabilities, or unusual signal patterns immediately visible.

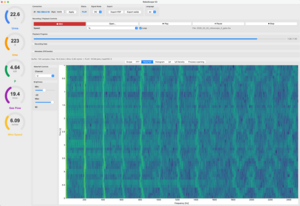

Spectral Analysis (FFT)

RoboScope offers a spectrum/FFT display to analyze frequency components in the measurement signals. This is particularly helpful for identifying disturbances, oscillations, or recurring patterns in the process.

In addition to the FFT view, RoboScope provides a waterfall diagram (spectrogram). While the FFT only shows "the current moment" as a frequency spectrum, the waterfall diagram displays the frequency components over time – i.e. a 3D spectral analysis (frequency × time × amplitude/color).

- x-axis: Frequency (Hz)

- y-axis: Time (s), e.g. the last 0 to 5 seconds, with new spectra starting at the top and "scrolling" downward

- Color / Intensity: Signal strength or amplitude (typically in dB)

This allows you to see at a glance whether and when certain frequencies occur, how disturbances change, whether frequencies drift, whether there are periodic patterns, or whether oscillations only appear briefly.

This is particularly helpful for:

- Finding temporally varying disturbances (e.g. EMI pulses, load changes)

- Observing resonances/oscillations

- Making recurring patterns in the process visible

- Comparing differences between U and I over time

Histogram

The histogram view allows the distribution of measured values over a period to be evaluated. This quickly reveals whether the process is running stably (narrow distribution) or whether scatter and outliers occur – a valuable basis for quality assessment, job comparison, and deriving meaningful limit values.

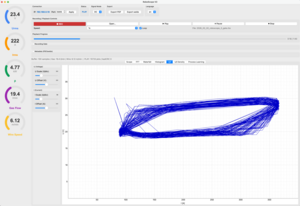

U-I Diagram (Characteristic Plot)

The U-I diagram plots voltage (U) against current (I) – i.e. not over time, but as a point cloud/curve in the characteristic space. Each measurement point from the live stream is plotted as a (U, I) pair. This provides an at-a-glance view of how the process "behaves electrically".

- Compact, stable cloud / narrow trace → Process runs smoothly, reproducibly.

- Wide cloud, outliers, jumps → Scatter, instability, unwanted events (e.g. short-circuit/arc transitions, contact problems, disturbances).

- Making process patterns visible: Many welding processes produce characteristic shapes (loops/clusters). Changes in wire feed, gas, contact tip, ground clamp, parameters, etc. shift or deform this signature – often recognizable earlier than in the time plot.

- Comparison of jobs/setups: The U-I diagram is excellent for directly comparing two jobs or two states: same shape = similar process behavior, different shape = parameter/process has changed.

- Limit values & quality logic: From the cloud, characteristic ranges can be derived (permissible "process zone"). As soon as points appear outside, RoboScope can interpret this as an indication of deviations/defects.

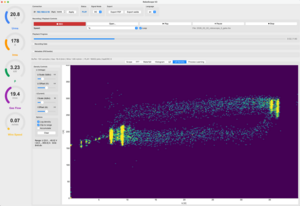

The U-I density diagram (density heatmap) shows the distribution of voltage U and current I as a point cloud with frequency coloring. Instead of displaying the signal over time, each measurement sample is placed as a point in the U-I coordinate system: x-axis = U (V), y-axis = I (A). The color intensity indicates how often a particular combination of U and I occurs – bright areas mean "frequent", dark areas mean "rare".

This allows very quick assessment of the process:

- Stability & scatter: A compact, dense cloud indicates a stable process; wide scatter indicates instability or fluctuations.

- Process states: Multiple clouds/clusters can indicate different operating states or transitions.

- Outliers: Rare events (spikes, disturbances) become visible as sparsely populated areas.

- Process window: The density distribution allows typical operating ranges to be identified and boundary areas to be defined.

Recording, Replay & Export

RoboScope can record measurement data, play it back (replay) for later analyses, and export it for external evaluations. This facilitates documentation, root cause analysis, and further processing in custom tools.

Capture welding data and export directly into a WPS-Maker 2 (.wpsx) template. Individual weld beads are recorded for a duration of 20 seconds and added to a subsequently editable list. When the list is complete, it is exported to a new .wpsx file, which can then be further edited in WPS-Maker 2.

Additionally, RoboScope supports exporting recorded measurement data in the open weldx data format.

This allows the high-resolution welding process data to be stored in a structured, long-term, and vendor-neutral manner.

The exported weldx files contain the time-resolved measurement signals (e.g. current, voltage, wire feed, gas flow) including time base and metadata, and can subsequently:

- Be supplemented with additional process and context data (e.g. weld seam geometry, component information, WPS)

- Be further processed in external analysis and research environments

- Serve as a basis for quality assurance, traceability, and AI-supported evaluation

Thus, RoboScope bridges the gap between live diagnostics at the welding station and sustainable, data-driven documentation of the welding process.

Diagnostics & Monitoring

In addition to the curves, RoboScope also provides technical insights such as timestamps, sequence numbers, and packet status. This allows quick verification of whether data arrives completely, synchronously, and plausibly – particularly helpful for network or integration questions.

Additional information

Manual4 MB

Manual4 MB Firmware Sensorbox 1.1.0896 KB

Firmware Sensorbox 1.1.0896 KB RoboScope Package MacOS270 MB

RoboScope Package MacOS270 MB